hot off the press

futureprint News

Browse our latest news in the print world below

Tags

- #SeikoOpenWeek 1

- 3D printing 18

- 3d design 1

- 3d printed electronics 1

- ACTEGA 1

- AI 3

- Accucheck 1

- Adphos 1

- Agfa Asanti 1

- BOBST 27

- BOURQUIN 1

- CYNGIENT 1

- Cartotecnica 1

- Chromaplex 1

- Colordyne 7

- Corrugated packaging 11

- DFE 1

- DODxAct 3

- ECOMMERCE 1

- ERP 1

- Farnborough International Exhibition & Conference Centre 1

- Finishing 3

- FireJet 3

- FuturePrint 13

- FuturePrint Leaders Summit 9

- FuturePrint TECH 3

- FuturePrint Tech Fest 4

- FuturePrint events 10

- Futureprint 5

- Futureprint partners 1

- GIS 9

- HP 6

- HP Pagewide 2

- Hymmen 2

- Höhn Display + Packaging 1

- INK CHEMISTRY 7

- INKJET CURING 2

- IST 1

- ITL 1

- Impresos Gráficos 1

- Industrial Inkjet 5

- Industrial Print 3

- Inkjet printheads 5

- Integration Technology 1

- K 2022 2

- Kammann 1

- Kao Collins 1

- LED 1

- LED Curing 11

- LED UV 13

Eco Print Virtual Summit – October 2023

Preparations for the Eco Print Virtual Summit are well underway, and our commitment to fostering a greener print industry remains steadfast

Discover what's happening now, what's new, and what's on the horizon at Printing Wonderland

Discover what's happening now, what's new, and what's on the horizon at Printing Wonderland.

Why Total UV Power is Important for UV LED Curing

Not all LED lamps with the same peak irradiance have the same total curing power. LED lamps with low energy density often have focusing optics that artificially bump up peak irradiance. Energy density is the key to ensuring adhesion and cure at high speeds.

How does LED compare to the incumbent drying technologies?

The advantages of UV LED technology are quite significant compared to mercury UV and solve most of the issues that result from mercury lamp use. Typical energy savings exceed 50% for applications converted from mercury-based curing to LED.

Go Green with Phoseon Technology to Save Green with Titan Energy

As a leader in the energy management industry, Titan Energy’s ability to generate savings associated with reduced overall consumption has created a trusted reputation throughout North America.

Integration Technology Further Strengthens Position in Europe with Sales Team Hire

Vrettos joins Integration Technology to further strengthen the European team.

Printing on the edge… and beyond

The printing of furniture edge bands with single-pass UV inkjet has been proven for many years, with Agfa’s Altamira Design PID inks meeting all needs. A variety of other decorative interior parts can greatly benefit from inkjet printing with the same Agfa ink set too.

Sustainability - Trust, Purpose, And Pain

In this episode, Frazer talks to Steve Lister, Sustainability Consultant for HH Global about his experiences in print, packaging and retail, where he believes sustainability is heading and the future of printing.

Phoseon Technology Partners with Vinsak Group in the Middle East to Support Flexographic Printing Installations

Phoseon Technology, the leader in UV LED curing solutions, announced an agreement with Vinsak Group to integrate Phoseon UV LED light sources into printing presses for the narrow web flexographic market.

Integration Technology Invests in Employee Career Progression During Growth Period

World Leading Developer of UV LED curing solutions Integration Technology announces further appointments to its managerial team during a period of continued growth.

Why UV LED Curing Has Become a Mainstream Technology

After 20 years in business, here’s what Phoseon Technology has learned from its customers

Phoseon Technology: UV LED Enables Versatile Applications

Phoseon’s UV LED curing technology is ideal for the UV curing of inks in digital inkjet, screen, flexographic and other printing processes.

UV LED Curing Brings Pinning Capability and More Choice of Substrates for Colordyne

Colordyne leverages Phoseon Technology UV LED pinning and curing lamps inside of their 3800 Series UV inkjet retrofit, providing equipment operators more flexibility.

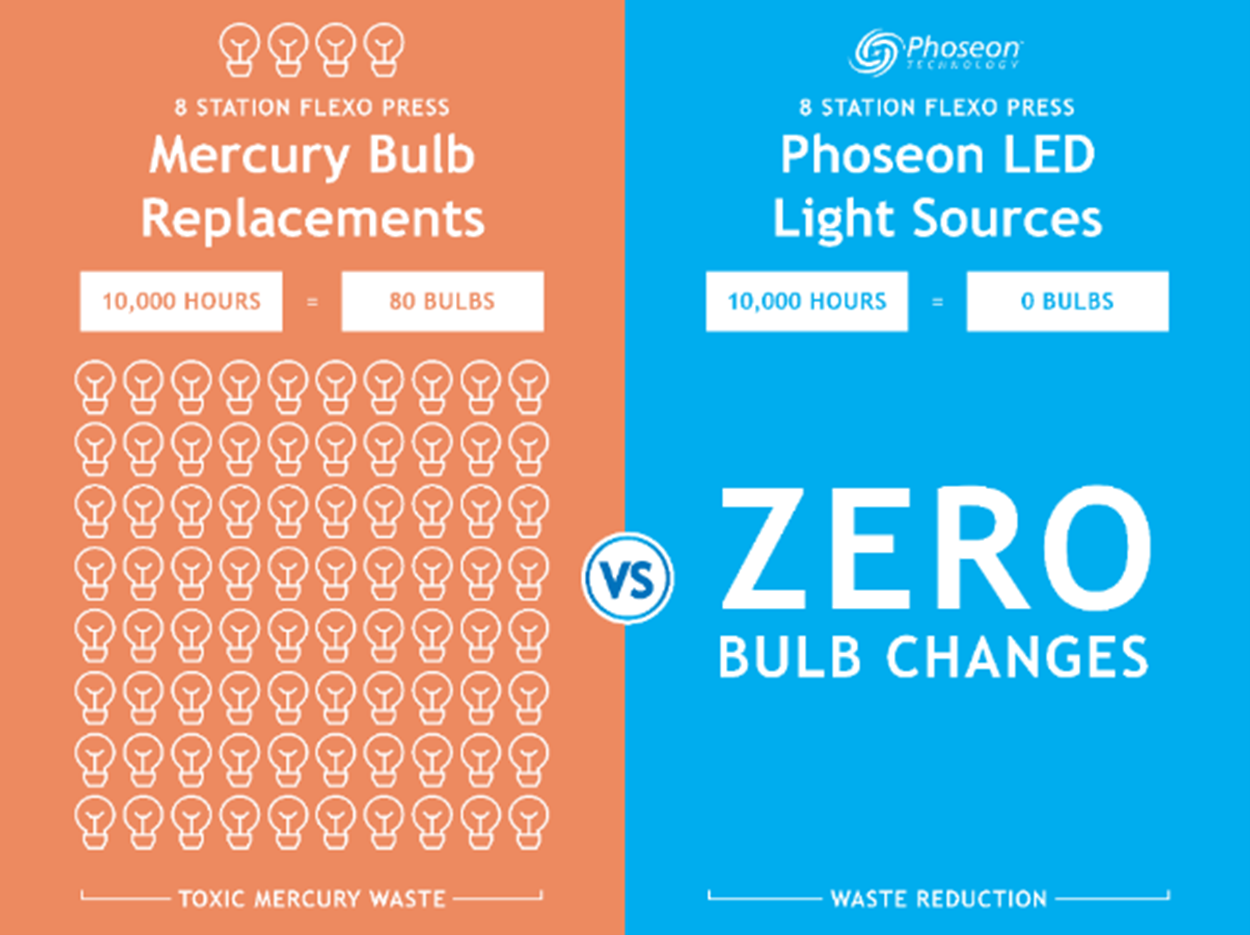

Why Converters are Upgrading from Mercury UV to LED Curing

UV LED curing technology continues to replace older mercury-based UV technology because it brings sustainability, reliability and productivity to printers and converters.

Rising Energy Costs Drive Faster Adoption of LED Curing

Phoseon Customer Saves More Than 70% on Energy Costs with Nexus ONE™ UV LED Curing.

Phoseon: The Converter Experience with UV LED Technology

UV LED light sources are ideal for high-speed curing in narrow-web presses, enabling end users to print on a variety of packaging materials at high speeds.

Keep Production Cool and Safe – A Guide to Substrate Temperature

UV LED curing has grown in popularity and become the new standard for printing, coating, adhesive, and electronics applications.

Phoseon UV LED Provides Significant Energy Savings

By replacing mercury lamps with UV LED curing systems, Phoseon customers have experienced energy savings of up to 85 percent. Discover the significant energy savings users of UV LED have experienced.

FireJet™ FJ240 - Phoseon’s Highest Power Air-Cooled UV LED Curing Solution

Phoseon’s FireJet™ FJ240 UV LED curing system is a high capability air-cooled LED lamp for printing and coating applications that require very high dose.

Understanding UV LED Technology

Phoseon’s patented Semiconductor Light Matrix (SLM)™ technology combines LEDs, arrays, optics and cooling to deliver the most sustainable, coolest operating, highly efficient ultraviolet curing products on the market.