Keep Production Cool and Safe – A Guide to Substrate Temperature

UV LED curing has grown in popularity and become the new standard for printing, coating, adhesive, and electronics applications. In fact, UV LED is considered a cold source since it does not contain the IR light which generates heat. In addition, advances in the design of light source cooling systems help to control and remove heat generated by the light source. Nevertheless, while customers are enjoying the increasing irradiance of LED light source, the temperature rise in substrates during curing still causes concerns. This article provides guidelines for operating the UV LED system in the appropriate setting.

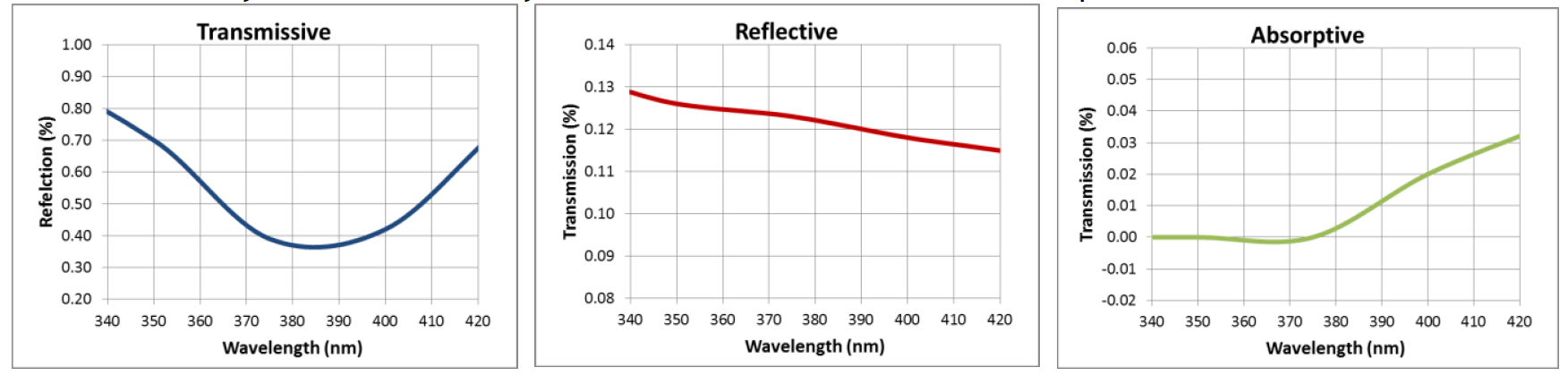

Figure 1: Material's Optical Property

In summary, UV LED is a cold source which does not generate heat itself. The increasing temperature on a substrate is not generated by LEDs but is the reaction of the substrate to UV light. The optical properties of the substrate itself has a significant effect on substrate temperature. External factors such as curing system’s power/irradiance, working distance and scanning speed also contribute to substrate temperature rise.

Hypothesis/Test

Every substrate has certain optical properties, in terms of Reflection (R), Absorption (A) or Transmission (T). For example, glass is among the few solids that transmit more than 90% of light, and Aluminum yields a reflectivity of around 90% in the UVA/visible spectrum.

Figure 2: Substrate Coating Optical Curves

Phoseon tested the temperature of three types of substrates with an ideal coating (Absorptive, Reflective and Transmissive) under UV LED curing. Figure 2 shows their optical properties. Two UV LED light sources, FireJet™ FJ200-150x20AC-14W-395nm and FireEdge™ FE300-110x10AC-5W-395nm were used as curing lamps. The light sources were turned on at room temperature, with full intensity, and moved at different scanning speed. The substrates were positioned at different working distances (WD). A thermal sensor was attached to each substrate to record the real-time temperature.

Figure 3: Test Setup

Results

The test results demonstrate that substrate temperature depends on external factors as well as the substrate optical property itself.

External factors are defined as all possible causes except the substrate itself. In general, substrate temperature depends on the curing system’s power/irradiance, working distance, scanning speed, and environment temperature. No matter which type of substrate, larger power/irradiance, shorter working distance, slower scanning speed, and higher environment temperature all lead to a higher substrate temperature. On the other hand, substrate temperature is also determined by itself. Transmissive substrate always has the lowest temperature as it does not absorb thermal energy. However, absorptive, and reflective substrates show more complex temperature curves.

The first test was to move the lamp at a fixed scanning speed but different working distances. As shown in Figure 4, beyond certain proximity (depending on UV output power/irradiance), the absorptive substrate had the highest temperature, followed by reflective, and then transmissive (A>R>T). This is obvious as the absorptive substrate captured more thermal energies than the other two.

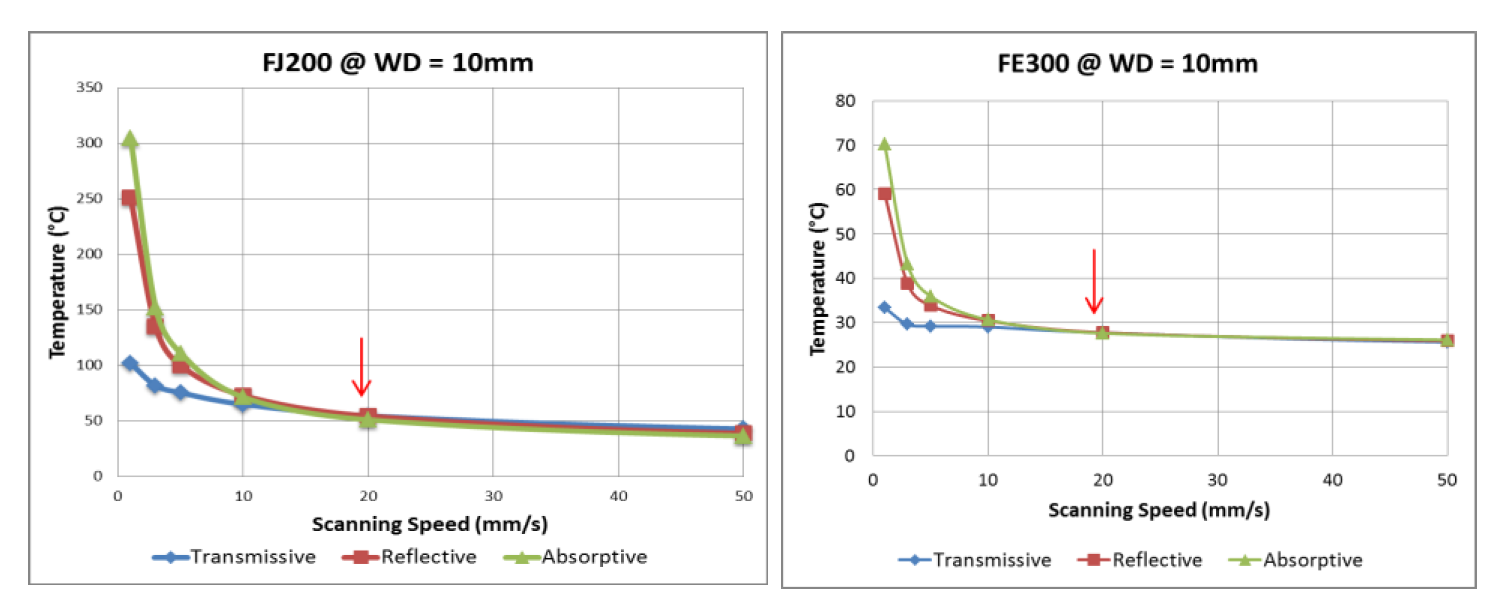

Figure 4: Effect of scanning speed on substrate temperature

However, as the working distance continued to get smaller, the reflective substrate had the highest temperature among the three (R>A>T). This was due to light reflected back to the lamp window glass and transformed to thermal energy, leading to further temperature rise.

The other test was to move the lamp at a fixed working distance but differ speed. As shown in Figure 5, when the scanning speed was very slow (less than 10mm/sec in this test), speed affected the substrate temperature significantly. In fact, substrate temperature increased exponentially as the scanning speed decreased. The absorptive substrate had the highest temperature rise, followed by reflective and transmissive (A>R>T). When the scanning speed was fast enough (above 20mm/sec in this test), there was little temperature difference observed. This demonstrated substrate temperature was mainly affected by external factors such as lamp power and environment temperature when scanning speed was high.

Figure 5: Effect of working distance on substrate temperature

Conclusion

How can converters ensure a successful curing process? Except providing the reliable and compelling curing system, Phoseon expects this substrate temperature article to guide users to actively understand substrate optical property, which results an efficient and optimized curing.