UV LED Curing Brings Pinning Capability and More Choice of Substrates for Colordyne

LED Pinning Lamps Between Every Color Combined with a Final Cure Solution Offers More Flexibility for Converters

Colordyne Technologies is a leading manufacturer of high speed, high resolution and low capital cost UV LED and water-based inkjet print engines. The retrofit modules are designed for integration into existing printing and converting equipment to create an affordable hybrid production press. Colordyne’s retrofit approach to digital printing allows label converters to seamlessly integrate process color inkjet directly onto existing production lines without the loss of current press functionality. As digital and hybrid print continue to gain popularity, label converters can take advantage of Colordyne’s inkjet technology to differentiate from the competition by offering greater converting potential and more flexibility.

Combining Pinning and Curing in Single Product Line

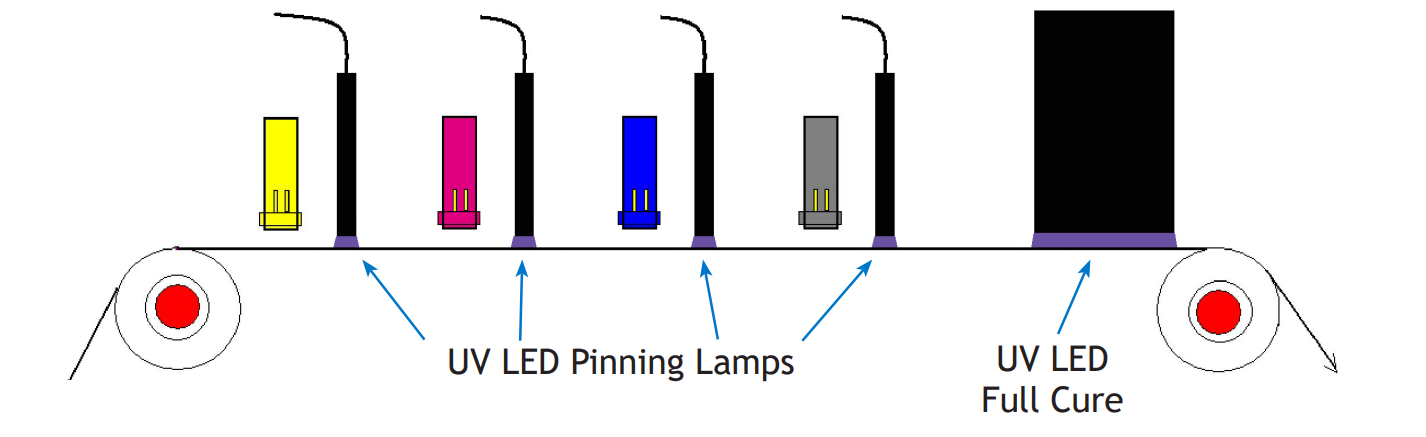

Colordyne leverages Phoseon Technology UV LED pinning and curing lamps inside of their 3800 Series UV inkjet retrofit, providing equipment operators more flexibility when it comes to maintaining consistent print quality on a wide range of substrates. And with the switch from Mercury to UV LED, they also provided our users with a platform that opens up more applications that they couldn’t produce previously. The system is available in 8.5”, 12.75”, and 17” print widths and can support up to 7 colors in the process direction while printing up to speeds of 240 fpm at 600x600 dpi. Production lines feature LED pinning lamps in between every print color, plus two final LED cure lamps located in the final cure assembly. These last two lamps feature a chill roll that further expands application range for the technology.

What is Pinning?

Before Colordyne invested in Phoseon UV LED lamps, it did not offer inter-color pinning. UV LED light sources allow digital printers to gel or freeze UV ink droplets quickly before they have time to spread out (referred to as drop or dot gain). The process of freezing ink droplets between print heads is called pinning. This is possible because the UV LED light sources are more compact than conventional curing systems and can be easily positioned between successive print heads. While pinning stops the drop from spreading, it leaves the ink flexible and soft enough for proper inter-coat adhesion to other ink droplets and for further handling. All pinned inks must finally pass underneath a final cure UV LED light, to finish the curing process.

Advantages of UV LED curing systems for Digital Printing include:

· Control of dot gain

· Low heat impact

· Instant on/off

· Stable & predictable output

· Small form factor lamps

· Inks stay flexible

· Intensity (pinning) control

· Improved image quality & line resolution

Sustainable, UV LED Curing Solutions

Consumers are choosing and prioritizing products that are eco-friendly, and this includes labels and packaging. Supporting a sustainable future and meeting consumer demands matter now more than ever for companies looking to retain and attract new customers. Colordyne is committed to creating affordable digital printers and presses that support the sustainability needs of its users and markets. Working with industry partners, Colordyne is dedicated to developing, engineering, and manufacturing innovative inkjet solutions. That is why Colordyne chose Phoseon UV LED curing solutions. Phoseon is committed to the well-being of the environment, and continuously work to reduce the environmental impact of the products that we manufacture. LED is the only sustainable choice for UV curing. With traditional UV curing processes, the tremendous heat associated with mercury UV lamps require a significant amount of electricity to operate. Phoseon UV LED technologies provide energy savings of between 75 and 85 percent compared to prior drying systems.

With Phoseon lamps, there is no need for fume extraction units to remove the gases generated by mercury-vapor UV lamps. UV LED is not only good for the environment, but also has a very positive effect on the finances, sustainability, health, and safety of company operations.