UV LED Curing for Digital Variable Data Printing, Coding and Marking

The compact UV LED curing light sources offer advanced capability and increased production speeds for coding and marking applications. The LEDs are instant on/off, so the UV is only on when ink curing has to occur. This saves energy and increases the life of the unit even further. With virtually no maintenance, low operating cost, and faster throughput, UV LED curing is the ideal choice for high-resolution variable data printing on a wide variety of substrates.

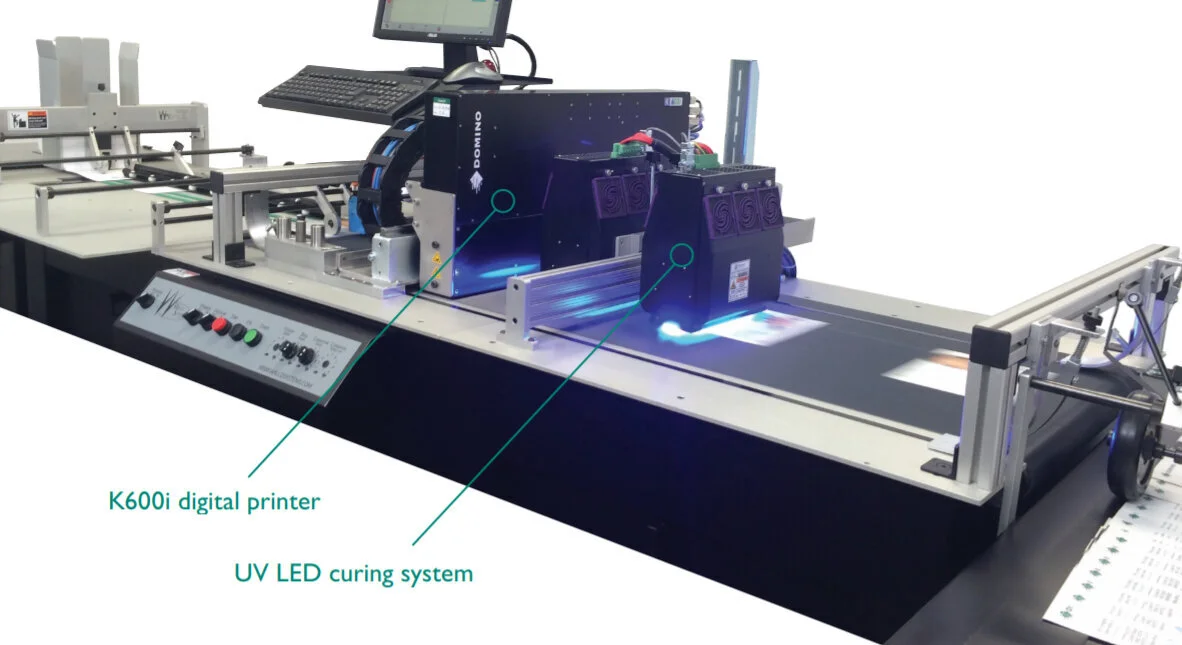

Domino utilizes Phoseon’s FireJet™ for Digital Printing & UV LED Curing

Domino offers digital printing solutions that are designed and engineered to minimize operator intervention and maximize throughput. Print high-resolution variable data such as bar codes, serialization, 2D codes, QR codes, addressing, personalization, graphics, and more.

UV LED Curing:

Dual-lamp UV LED curing system provides numerous advantages over traditional arc lamp curing methods.

• UV LED can be positioned on the mail base at close proximity to the K600i printbar, resulting in a “quick cure” and producing optimal print quality as the ink doesn’t have the opportunity to bleed-in or flow onto more glossy substrates.

• instant on/off

• no exhaust piping required

• no 3-phase power requirements

Domino K600i ink jet printer is a high-speed digital black plate UV ink jet system that prints 600dpi variable data up to 246 feet/ minute onto a wide range of uncoated and coated sheet or web materials. Applications include printing onto labels, tags, tickets, forms, security products and direct mail. Using UV curable ink, the K600i is a non-contact form of printing with few moving parts. That coupled with Domino’s iTech features result in a highly reliable and efficient variable data printing system.

Automated stitching of printheads allows for seamless printing across the entire print bar. Automated printhead alignment & image stitching, achieved through. StitchLink micro-motor controller technology. Easy and accurate set-up, no manual stitching of printheads. Fast make-ready, less material waste, and excellent print quality. Print seamless alphanumerics, logos, graphics & 100% scannable “Grade A” verifiable bar codes.

User selectable droplet sizes allows for less ink consumption and therefore lower costs. Print on a wider range of materials with crisp print quality. UV LED Technology Domino’s K600i ink jet printer utilizes Phoseon’s FireJet aircooled UV LED curing products. The compact UV LED curing lamps offer advanced capability and increased production speeds. The LEDs are instant on/off, so the UV is only on when ink curing has to occur. This saves energy and increases the life of the unit even further. UV LED curing is the ideal choice for high-resolution variable data printing on a wide variety of substrates.

UV LED Curing System

• Phoseon FireJet FJ200 8-watt air cooled LED curing system

• 75mm - 225mm wide lamps requires one (1) 220V, 20amp single phase power drop

• 300mm - 375mm wide lamps requires two (2) 220V, 20amp single phase power drops

• instant on/off

• no exhaust piping required

• no 3-phase power requirements

UV LED Advantages for Converters:

UV LED brings proven reliability, superior performance, and innovative technology to digital printers. An additional advantage is significantly lower energy costs. Greater savings are gained for converters that transition to UV LED lamps from traditional UV mercury arc lamps, which use 70 per cent more electrical power to operate than low-heat, low-energy UV LED technology. UV LED lamps also require much lower maintenance service than traditional UV lamps, due to their much longer life.

For more information on UV LED technology for digital printing visit Phoseon Technology HERE.