Sustainable Label Printing: First complete UV LED Printing Press in Poland

The family-run printing company Eticod from Katowice, Poland, founded in 1994, focused on the sustainable production of labels at an early stage and has already invested in photovoltaic systems and heat exchangers in the past. With the investment in UV-LED for drying, the CO2 emissions at Eticod are reduced even further.

With the construction of the new factory building, production could be expanded and made even more sustainable. Eticod owns 5 modern flexo printing presses and 2 digital HP Indigo printing machines, but what you will not find at Eticod are chillers. The water is naturally cooled in the earth, fed into the highly efficient water supply of the factory, and thus used to cool the presses and the building in the summer.

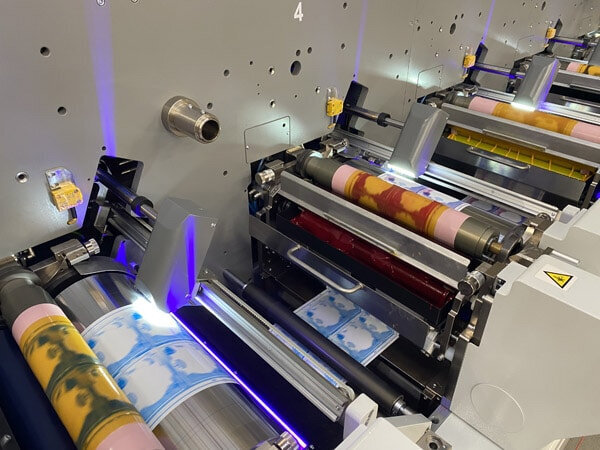

To reduce CO2 emissions even further and to make production even more efficient, Eticod has decided to invest in UV LED technology. At the beginning of the year a Bobst M5 430, 10-color press with UV-LED curing was successfully installed and put into operation. The machine consumes approximately 60% less electricity, which corresponds to an annual saving of approximately 50 kWh or 200 tons of CO2.

Aron Huc, son of company founder Jacek Huc, is very impressed with Phoseon UV LED curing technology: “Phoseon UV-LED ensures constant and efficient curing on all colors and at all speeds. The fact that we do not need any replacement lamps or any other spare parts, as well as the longevity of the Phoseon UV-LED lamps with an achievable lifetime of over 60,000 operating hours, give us security and predictability in our production. UV-LED lamps do not emit any ozone, which means that no extraction system had to be installed. UV LED is not only good for the environment, but also has a very positive effect on the finances, sustainability and health and safety of our company. "

In 2002 Phoseon Technology Inc. based in the USA was the first company worldwide to develop UV-LED lamps for industry and produces them in its own factory at its headquarters near Portland, Oregon, under strict ISO 9001 quality standards. Phoseon UV-LED lamps achieve a lifetime of more than 60,000 hours in the field and in internal service life tests, which corresponds to a lifetime of approximately 15 to 20 years on a flexographic printing press. With over 2,500 systems installed worldwide and over 300 patents, Phoseon is the market and technology leader in UV LED curing in flexographic printing.

ETICOD exported 40% of its production to Germany in 2020 and produces for the largest European brands. It is one of the most modern companies in Poland and invests in new machines and equipment every year.