The Top 10 Reasons Customers Choose Phoseon LED for Flexographic Printing

Phoseon’s proprietary solutions offer an improved converter experience with UV LED technology. UV LED opens the door to new revenue opportunities with the ability to print on heat sensitive and thinner substrates, offering increased profitability for printers and converters. Phoseon solutions offer higher print quality, faster curing speeds, and a more reliable curing process. New revenue streams become available with the unique UV LED technology benefits, in addition to saving energy and eliminating replacement part costs. Here are the top 10 reasons customers choose Phoseon LED for flexographic printing.

#1 Digital Curing 4.0

The digital revolution has reached the curing technology. With Phoseon UV LED your curing system will be instantly available at any time with consistent parameters! Why invest in 50 year old curing technology when digital UV LED curing is readily available? Invest in your future now!

#2 Futureproof Investment

Customers express that prior to switching to Phoseon LED lamps, they were spending close to 40-50 thousand dollars a year on UV bulb replacements for their press. Don’t waste your money on old curing technology which will be obsolete soon, and don’t waste your money on hybrid technology which only is useful for mercury lamp suppliers. Invest in your people and your company’s future! Invest in UV LED and a lifetime of no spare parts and no worries about mercury regulations!

#3 Upgrade or New Press?

No matter if you are upgrading or thinking about a new press, Phoseon is here for you with its latest state of the art technology supported by over 300 patents. This is true state of the art technology all Made in the USA. Upgrading? Then experience our most energy efficient air-cooled lamps. New machine? Yes, we do have water cooled lamps as well!

#4 Energy Savings

Between 50-60% less energy consumption when compared to mercury. Even more energy savings when using air cooled lamps as chillers are not required! Did you know that 70% of energy consumed by your flexo press falls to the curing system!? Keep cool and go green!

#5 Maintenance Free

Welcome to a world which is virtually free of maintenance! No shutters to maintain, no reflectors to clean, no hidden costs, no unexpected machine stops! This is the reality of UV LED made by Phoseon! Just clean the emitting window from time to time and you are ready to go!

#6 Proven Lifetime of More than 60K Hours

Phoseon is the only company in the industry which can say that we have a proven lifetime of more than 60,000 hours! This is UV LED reality made by Phoseon. 60k hours means in UV LED terms that we count only the ON time as turning lamps on and off is instant! (Less than 20ms)

#7 Less Infrastructure

No ozone = no exhaust which means in return no unnecessary infrastructure and no maintenance of this infrastructure.

#8 Virtually No Spare Parts

We do not live off our spare parts because there are none! Welcome to a new reality – the Phoseon way of life!

#9 Process Control

“The instant on/off Phoseon LED lamps allow us to gain up to 30 minutes of production time per day and per team.” - Christophe Pichard, production, and technical manager at Sopano, France – after retrofitting his flexo printing presses with air cooled Phoseon UV LED lamps.

#10 High Machine Uptime

Before switching to UV LED, when running with UV arc lamps, Central Valley Labels, USA was averaging around 15,000 units an hour. With the new process, the company was able to reach 25,000 to 28,000 units an hour. Because the new presses run so fast and true, most of the production times for labels run on these presses have been effectively cut in half. As a result, the company has eliminated the need for night shifts.

It’s Time to Upgrade

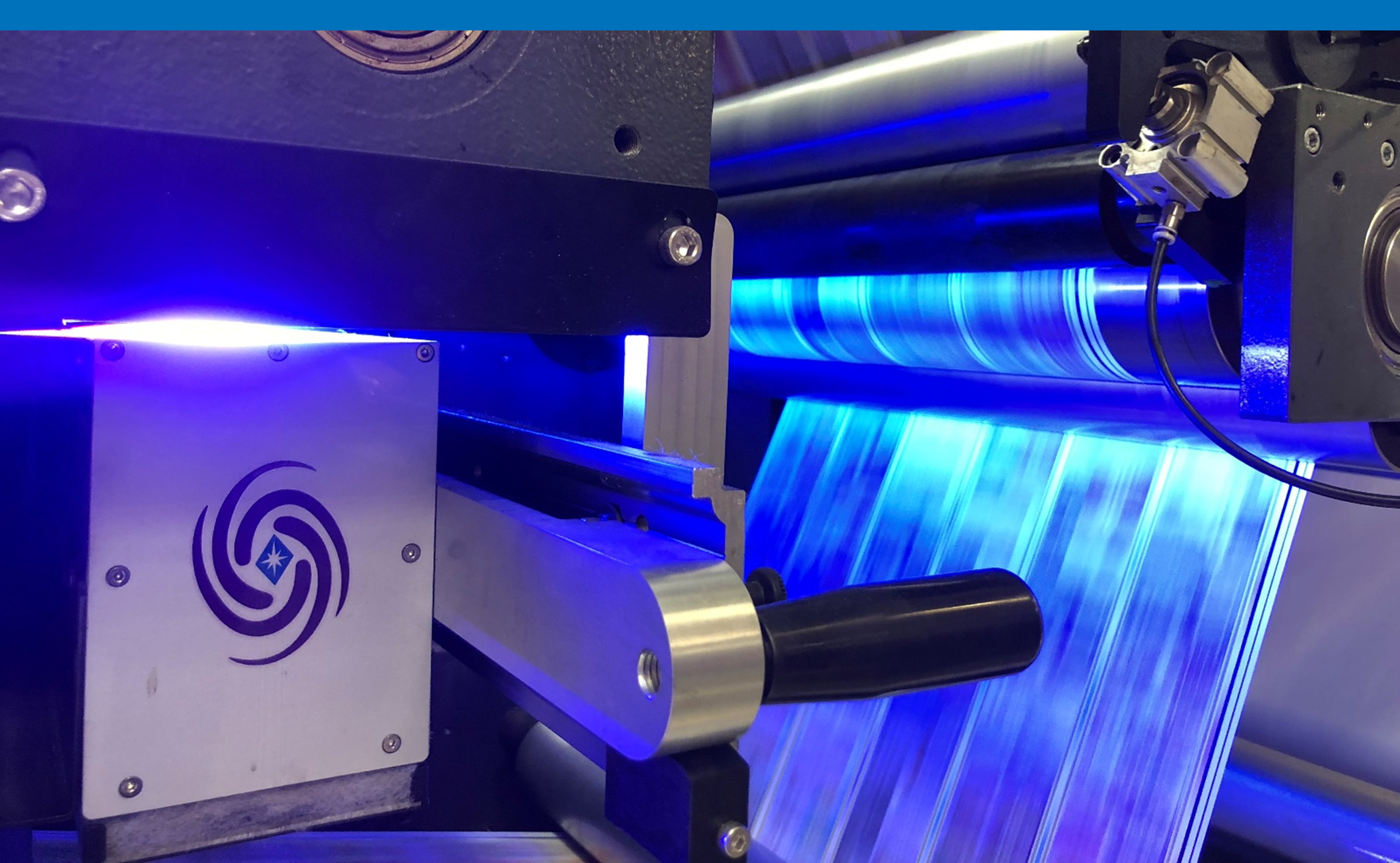

Are you interested in UV LED technology but not sure how to get started? Phoseon offers fully integrated solutions for narrow-web upgrades that consist of station-by-station building blocks including light sources and Flex Tower power and control systems. Upgrade your Press Today

For more information about Phoseon Technology products and services, please contact: info@phoseon.com or visit https://phoseon.com/industrial-curing/

About Phoseon Technology

Since 2002, Phoseon Technology pioneered the use of LED technology for Life Sciences and Industrial Curing. Through our relentless innovation, we deliver high performance, reliable and patented LED based solutions. Our strong focus on customer collaboration has resulted in world-wide market leadership position and presence. Phoseon is an ISO9001 certified company manufacturing award winning products that are covered by more than 300 patents worldwide. We uniquely focus 100% on LED technology therefore ensuring superior reliability, business economics, and environmental benefits.