Inkjet Fluid Testing: Why Modular Equipment is the Key to Success

By Mark Bale

In my previous FuturePrint blog on the topic of fluid testing for industrial inkjet [1], I highlighted how any R&D laboratory seeking to demonstrate the potential of their ink or fluid needs to consider how to print in addition to just jetting. At DoDxAct, we have always followed this mantra and thus are able to develop expertise and experience that means our advice and training is fully supported by experimental results. In this post, we describe in more detail the importance of modular equipment design for the fullest possible application coverage to serve our clients.

Client Needs Drive Lab Innovation

DoDxAct has based its world-leading independent laboratory waveform and print optimisation services on the unique equipment combinations we have developed over the last 2½ years. Initially collaborating with Imagexpert, we ran all our experiments by making customised augmentations to their off-the-shelf solution, the Jetxpert print station [2]. The prototyping examples given last time were just a small sample of what we had worked on during our first 18 months, mostly using temporary set-ups like that shown below for UV curing, where the UV lamp was kindly loaned by fellow FM Partner UV Integration Ltd.

DoDxAct’s Imagexpert print station with Ricoh GH2220 and ITL lamp

However, when working with a client to develop a novel 3D process in early 2019, we reached a limitation in what the Jetxpert could make possible due to restricted geometry, especially in terms of the print gap over the conveyor. It was difficult to achieve our target of making multi-layered printing into powder for 3D binder formulation testing and optimisation. Our solution was to combine a new transport system with the then newly-launched Meteor dropwatcher system. We thus created a modular design to enable quick adaptation to different inkjet problems such as 3D and print-to-shape, but also enabling rapid prototyping of multiple colours with multi-row print heads for packaging, for example [3].

Capability Development Through Collaboration

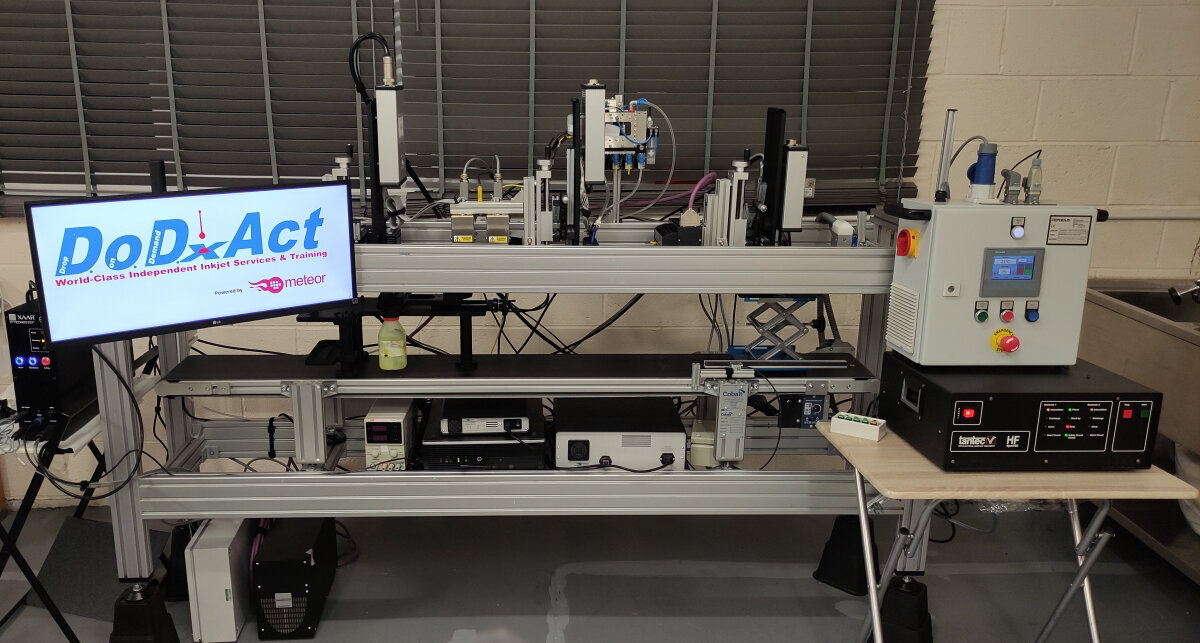

In recent months we have developed this system to make it even more powerful. We have taken full advantage of the multi-head capability of Meteor’s hardware and software to produce a platform for sustained development on multiple client projects in parallel, without repeatedly spending days of time altering the configuration. The photo below shows the system running three leading print recirculation-based piezo print heads for 3D/functional fluid deposition, augmented with inline corona treatment, UV cure, and IR drying.

DoDxAct’s print rig with built around the Meteor Dropwatcher, pictured under the Seiko RC1536

Beyond the key relationship with Meteor, the ability to configure the system as needed relies on strong relationships with the printhead manufacturers. In addition to the Dimatix, Seiko and Xaar printheads integrated above; DoDxAct is equipped for waveform development on Epson, Konica Minolta and Ricoh head technology. For ink supply, we make use of a Xaar Hydra for high flow recirculation, and Megnajet LFR for heads where lower throughput is needed.

Looking at supporting technology for pre- and post-treatment/drying we have invested in the ITL UV system shown above. Currently though, the corona treater and IR driers featured have both been sourced as temporary rentals, with the kind support of Tantec UK Ltd and Heraeus Nobelight, respectively. The next step will be to expand to UV-LED (Phoseon) and NIR (Adphos), driven by the needs of our client projects.

The importance of this collaborative approach was the subject of the session that I hosted for the second FuturePrint virtual summit in 2020 [4]. As highlighted then, the ink/fluid manufacturers are also an important part of that collaborative ecosystem, since there is no point in having a printer and no ink! As a result, we engage on behalf of our clients with the leading suppliers of jetting ink technology, several of whom are FuturePrint partners too. We have conducted projects with product offerings from Actega, Agfa, Marabu, Mexar, Sakata-INX, Siegwerk, Sun Chemical and Tiger Coatings. In the image below, the Meteor dropwatcher is used to produce consistent drop sizes through waveform tuning across different supplier inks (and viscosities) to make meaningful comparisons in print quality.

Drop images from the Meteor firing Xaar XJ1201 in greyscale

We also like to expand our raw material knowhow by working with suppliers including Lubrizol, Evonik, Byk and others. Our current “homework” for the next conference presentation is to develop our own mixtures using UV acrylate materials from leading supplier Arkema and look at relative head performance using monomer with improved properties for functional and 3D printing.

Modular is Best

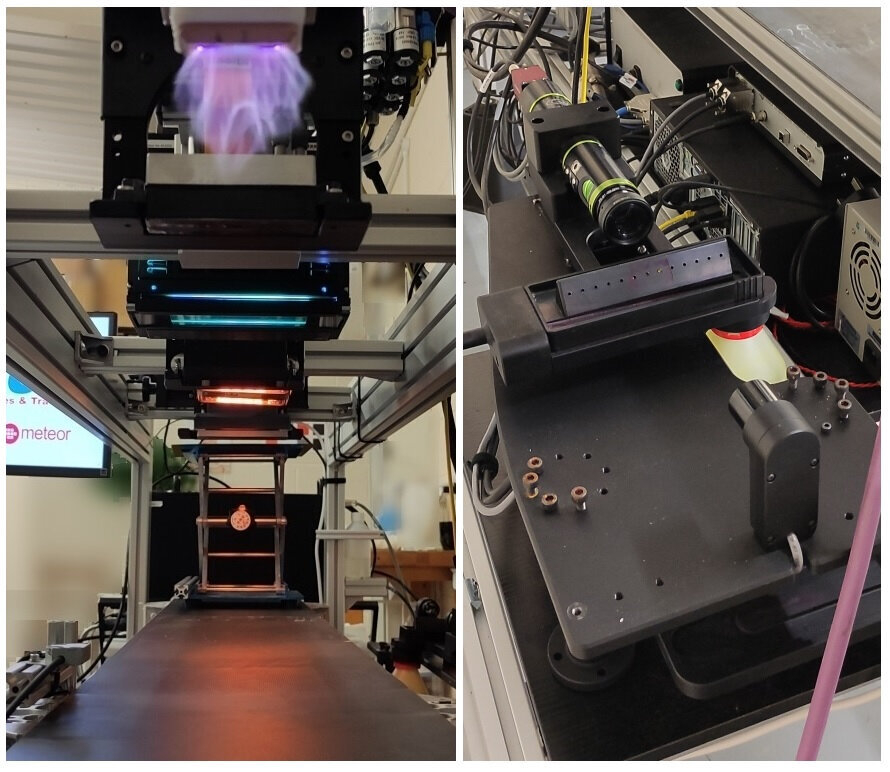

To make the system as flexible as possible, the whole design is centred around the Meteor HDK components of their dropwatcher system, incorporating custom heads mount and head driver unit. Where needed this allows for the same quick changeovers between heads as is possible with the standalone (non-integrated) offering [5]. The custom mounting positions for each head, shown below for XJ1003, allows for a large-range z-adjustment that permit the heads not currently being used to be retracted out of harm’s way, whilst the UV/IR driers can be swapped in a matter of seconds. As there is independent adjustment of the driers relative to the heads, different geometries are easy to implement, to control uniformity for example. Serial curing configurations are also achievable, such as the IR drying of a UV-hybrid ink prior to UV exposure.

Example modular arrangements using Xaar for UV inks and Dimatix SG1024 for aqueous

The print table is simple in implementation since this allows utmost flexibility in controlling the print gap. The position encoding comes from a linear strip to ensure the read-out is closer to the actual print position, thus overcoming some of the issues seen with conveyors with shaft-mounted rotary encoders. The flat printing surface can be augmented with fixtures that are customised to the application needs (eg. print-to-shape) and the open geometry required to accommodate the dropwatcher also allows for a binder-jet build bed to be accommodated (proprietary so not shown). During printing operations, the Meteor dropwatcher optics remain connected, but safely stored out of the path of the conveyor as shown in the next photo.

View along the belt showing corona, UV and IR with dropwatcher optics safely stowed

Using this Meteor-based equipment platform DoDxAct intends to meet the needs of a range of clients in 2021 and beyond, by offering a uniquely flexible service for waveform development and print process tuning. We already have plans for a 4th head position, which will be the limit due to the conveyor length and the footprint of the dropwatcher system.

For those customers that have specific drive electronic requirements, we retain the flexibility of using the Imagexpert Print Station, already integrated for interchangeable operation between Meteor and GIS hardware with both high- flow and low-flow ink systems and soon to be adapted to work with the same quick-mounting for IR and UV installation. To meet specific client needs we can also mix and match the full extent of our equipment capability between the two systems.

Thanks for reading, and in the spirit of the great Eddie Cochran, do not forgot to follow the “Three Steps to Heaven” approach, which modified to industrial inkjet goes something like:

(1) Follow DoDxAct on LinkedIn [6] to hear about our future laboratory capability developments.

(2) Visit dodxact.com today to find out how DoDxAct can leverage our expertise in materials testing and waveform optimisation to realise your inkjet R&D ambitions faster than you thought possible.

(3) Follow the link there to get in touch and ensure your business can benefit from truly independent expertise that is recommended by the world’s leading suppliers.

References

[1] https://futureprint.tech/the-futureprint-blog/markbale

[2] http://jetxpert.com/products/print-station/).

[3] M.Bale, Methods for Optimising Ink and Coatings for Packaging, IS&T Print4Fab, 2019

[4] https://virtualsummit.futureprint.tech/talks/importance-of-collaboration/

[5] https://www.meteorinkjet.com/products/dropwatcher/

[6] https://www.linkedin.com/company/dodxact-ltd/