The Power of Prototyping

The variety of inkjet applications has exploded in the last 5 years, with inkjet being used as the key part of many different manufacturing processes. With an ever-widening choice of print heads to suit application needs of print speed or droplet size, it is the ink chemistry and surrounding print process that then defines the key design inputs to the final production machine. It has, therefore, become more and more important to test for materials suitability at a feasibility stage of any substantial R&D project and that learning is catalysed by innovative use of commercially available laboratory-scale equipment. In this article, we explain why it is important to prototype early in a project and gives some examples of what we’ve done at DoDxAct.

The Equipment

A core piece of equipment in R&D lab for many years has been the drop watcher, which combines an LED light source synchronised to the print head signals and camera to provide images of the drops from a head. By firing the head and looking at these images the all-important electrical signals, known as a waveform can be tuned (see https://www.imiconf.com/post/waveform-as-a-tool-for-industrial- inkjet-printing). One such example, shown below, is produced by UK supplier Meteor Inkjet Ltd.

For industrial applications, that is just the beginning of the story. It is what happens next when those newly-perfected droplets hit the intended surface, that defines the true success of the fluid. For that reason, any laboratory seeking to demonstrate the potential of their product offerings needs to consider how to print. That’s obvious, right? But it is often overlooked at the earliest stage of product testing because it is dismissed as the next step in the development process. This is simply not the case since the printing performance can be the make-or-break of a formulation even if it jets perfectly.

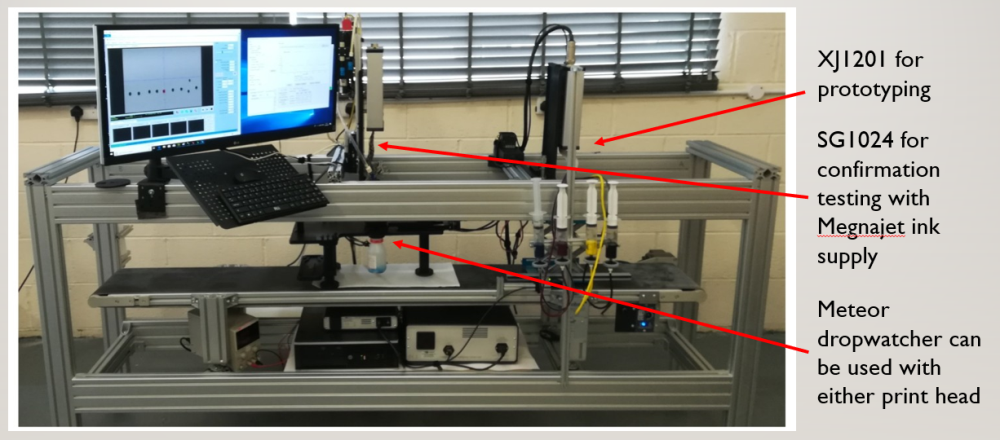

The most efficient solution to this problem is to combine dropwatcher with a print system of some description. This had been done in niche products for printed electronics applications, like the Dimatix DMP or Pixdro LP50, but those tools are limited in their functionality and flexibility, either by the print head size or the single-box design. They are also multiple-pass printers, whereas most tools for inkjet manufacturing are single-pass for productivity reasons. The solution is a combined dropwatcher / print system with single-pass -capable print heads that can be filled with smaller amounts of inks and yet produce relevant results to allow for screening of materials to demonstrate feasibility. We have two such systems, one that is commercially available as a complete system (the Jetxpert Print Station as shown in the cover photo) and a second that we have produced by combining different 3-rd party components. This in-house-built system, shown below, features a conveyor and a frame for supporting multiple print heads all capable of being run with the afore-mentioned Meteor dropwatcher. Each head is individually adjustable in position.

It should be noted that mounting multiple print heads onto one conveyor or linear drive is not new, but the inclusion of a dropwatcher that can be positioned under any head to speed up the prototyping is not often seen. Also important is the vertical space made available for different-sized parts or even a 3D print bed, and or for trying different drying regimes. With a conveyor system, continuous feed can also be possible, where the application requires it.

Packaging Example

So now we’ll give some examples of what we can do to determine whether the chemistry achieves what we’re looking for. Our first example is optimising the interaction between flexo coatings and inkjet coloured inks for packaging. This is a key area for current chemistry development from suppliers of inks and primers/coatings and the strong influence that can be obtained is shown below. The red box detail reveals how ink drops behave when the surface does not wet out (spread), whilst the yellow box highlights the effect of different primer coats, which influence spread and “bleed” between colours.

These revealing experiments were conducted with just 150ml of inks and 50ml of primer and so iterative testing of fluids under different process conditions are possible to be done very quickly. The ink interaction was filmed in real-time to allow for design of printer to be understood in terms of optimal print-to-dry time for the process.

Functional Decorative Example

One of the ways inkjet has captured the imagination of designers is through the flexibility of customised graphics, like those used to wrap cars and buildings. When the print is going to be part of the architecture years to come, the material challenges are even more important and getting the combinations right is crucial. As for our packaging example combining inkjet with analogue coatings is a route to getting the best possible performance. In the example below, we combined 5-6 different aqueous and solvent primer/varnish materials with UV inks to compare print quality (ink affinity) and outdoor fastness on a structured (2.5D) surface of aluminium.

The emphasis is not on the print quality but on finding the best combination of materials to meet needs (weathering, non-slip) whilst demonstrating with simple print patterns the type of customisation that is possible. This now commonly includes printing topography and colour which can take advantage of having different print head types in one system.

Textile Example

Our final prototyping example comes from the interesting concept of printing a yarn inline with embroidery or weaving. This concept has actually now been commercialised by Coloreel®. With the addition of a relatively simple apparatus for transporting the yarn the uptake of the colourant (ink) can be image on the dropwatcher and the output simultaneous in real-time using a colour camera. This allows for the penetration and volume/length to be optimised.

Recognising the power of Prototyping

So, what we hope to have shown is that in a range of industrial applications, it is the materials and process combinations that matter just as much as the fluid jetting. It is possible to adapt equipment that is readily available in the market to a wide variety to problems and help solve problems posed by today’s wide range of potential uses. At DoDxAct we help our clients utilise their existing R&D resources to access new applications by offering training and practical consultancy on inks & test methods. We can also advise on new equipment needs, including print head selection & supporting hardware, demonstrating solutions using our own laboratory facilities, often in collaboration with suppliers like Global Inkjet Systems and Meteor Inkjet.

We also develop waveforms and perform material prototyping on a contract basis.

**All tests were performed with the Ricoh GH2220 Inkjet head on DoDxAct's Jetxpert Print Station

Email Mark Bale for more information.

Check out the DoDxAct website.