DoDxAct’s Pandemic Response – Driving Lab Capability

By Mark Bale

In the FuturePrint events in October 2020 and February 2021, the effects of the pandemic on print and the hopes for the future have been a big focus. When the UK lockdown was announced in February 2020 DoDxAct had only been trading for just over two years, and was building a reputation for combining its expertise in inkjet process optimisation with a practical support through lab testing. Almost 50% of our business relied on travel to customer sites, either providing print head and waveform training or assisting directly with the design and build of highly-customised inkjet deposition devices.

Our solution to meet this gap was to consolidate our offering in our UK-based laboratory, leveraging our passion for all things inkjet print head and combining it with our experience testing many different types of fluids. Building on our recent innovation to prove single-head multicolour print prototyping on inks and primers, as we spoke about in our first Futureprint blog, we provided testing services to labs that were struggling to get work completed on time with a more limited workforce.

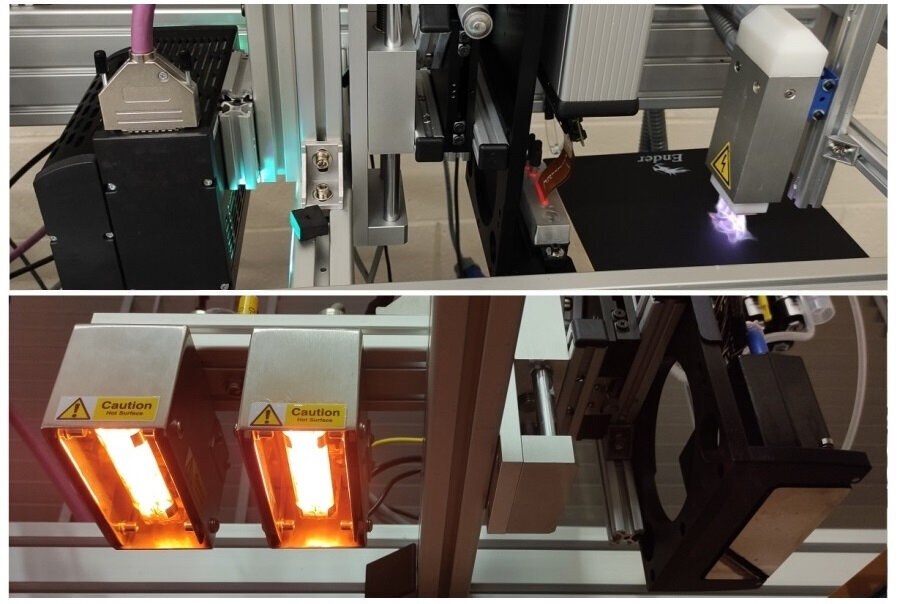

It became clear that to pivot towards focusing almost exclusively on lab services in this way we needed to continue to invest in equipment, so we took a hard look at what we could do and added functionality where it could have an impact. At short notice, FuturePrint partner Integration Technology was able to deliver a lamp for us to undertake a project using aqueous-UV inks which were printed using our system developed in collaboration with Meteor Inkjet.

When it comes to projects withs specific chemistry needs, we do not formulate ourselves but use our links with well-known providers of inkjet inks to find the right solution for our client’s needs. Then we help by analysing and proving which print heads will deliver that chemistry with the coverage, speed and resolution being sought. This gave us the idea for the second FuturePrint summit session we did in October, bringing together other FuturePrint partners Sun Chemical, Integration Technology, Ricoh and Meteor.

Throughout the Autumn of 2020 and into the Winter months we continued to invest, adding Seiko and Epson to the list of print head partners (complementing FuturePrint partners Fujifilm, Xaar, Ricoh) and upgrading our customised print rig to support up to three heads with a more modular approach to changeovers. We have since added Adphos NIR drying to complement our UV capability.

As result of our efforts, we have started 2021 a different company to how we started 2020: with a lab that is even better equipped to deliver on a more diverse range of projects and chemistry types and an even stronger network of partnerships with which to support that testing. Good thing too, since UK entered another lockdown period!

We were so proud of this achievement that we decided that the best way to highlight the value we place on laboratory testing was to demonstrate it in action as part of the FuturePrint conference. It took quite a bit of planning and more than a little bit of preparation, including ink contributions from partners Sun Chemical and Agfa, but we were incredibly pleased with the feedback received last week.

If you missed it, catch the recording here. It features equipment from an impressive list of FuturePrint partners, adding ink systems from our friends at Global Inkjet Systems to all those already mentioned above.

Most importantly: If you think we can help your project then don’t hesitate and contact us today.

Follow DoDxAct on LinkedIn.