The Perfect Cocktail

www.integrationtechnology.com

From the somewhat facetious title, the analogy of creating a UV-curing coating is not too far from the truth.

There are a number of market drivers advancing the adoption of LED curing as the go-to standard for the print market:

Advancement of technology

Commercial affordability

Availability

Environmental impact

Energy consumption

Durability

Removal of heavy metals

Reduction of pressroom ozone

What is less generally understood is the performance variations when switching to an LED system.

To ensure optimum performance and in turn the maximum benefits, it requires a careful selection of components and an understanding of their influence on the total matrix.

The lamp choice

The lamp configuration and setup

Machine speed

Coating applicator

Substrate and ink choice

Coating formulation

End requirements for the finished print work.

At VOKA our area of expertise is on point 6. where we are involved with the development and qualification of coating technology for OEM and Global consumable manufacturers.

The purpose of this document is to give an overview of the properties and behaviours of LED curing technology and how they vary from conventional Mercury curing lamps.

Compositions are not significantly different to conventional UV coatings. The liquid normally contains:-

Like coiled springs these molecules are primed to react with the slightest amount of encouragement. When this happens the liquid solidifies into a gelled mass or a rock-hard plastic, dependent on the type of reactivity the molecules have or the degree to which they have reacted.

For example, partially cured tetra functional will be a gelled mass, as will a fully cured monofunctional formula.

(To avoid unexpected reactions there are inhibitors in the coatings to stop the reaction from occurring unexpectedly)

Based on this theory, a formulator can dial the level of hardness and properties of the coating depending on the application and requirements.

The principle of creating a polymer from these starting blocks is clear but the cocktail is not complete.

Without further additives the pre-polymers can interact with light and begin to gel but it will be a slow and impractical reaction.

To ensure a rapid and complete reaction photoinitiators are employed.

Photo : Greek origin – light

Initiate: Latin origin – to begin from

Simply put – the light starter!

The chemistry is complex and there are numerous options available to the formulator however each initiator is most effective at a particular wavelength of light. So we first have to start with explaining the wavelength properties of light and this will give the best insight into the difference between mercury and LED curing.

With colour, longer wavelengths are lower in energy (towards the right side of the spectra illustrated below).

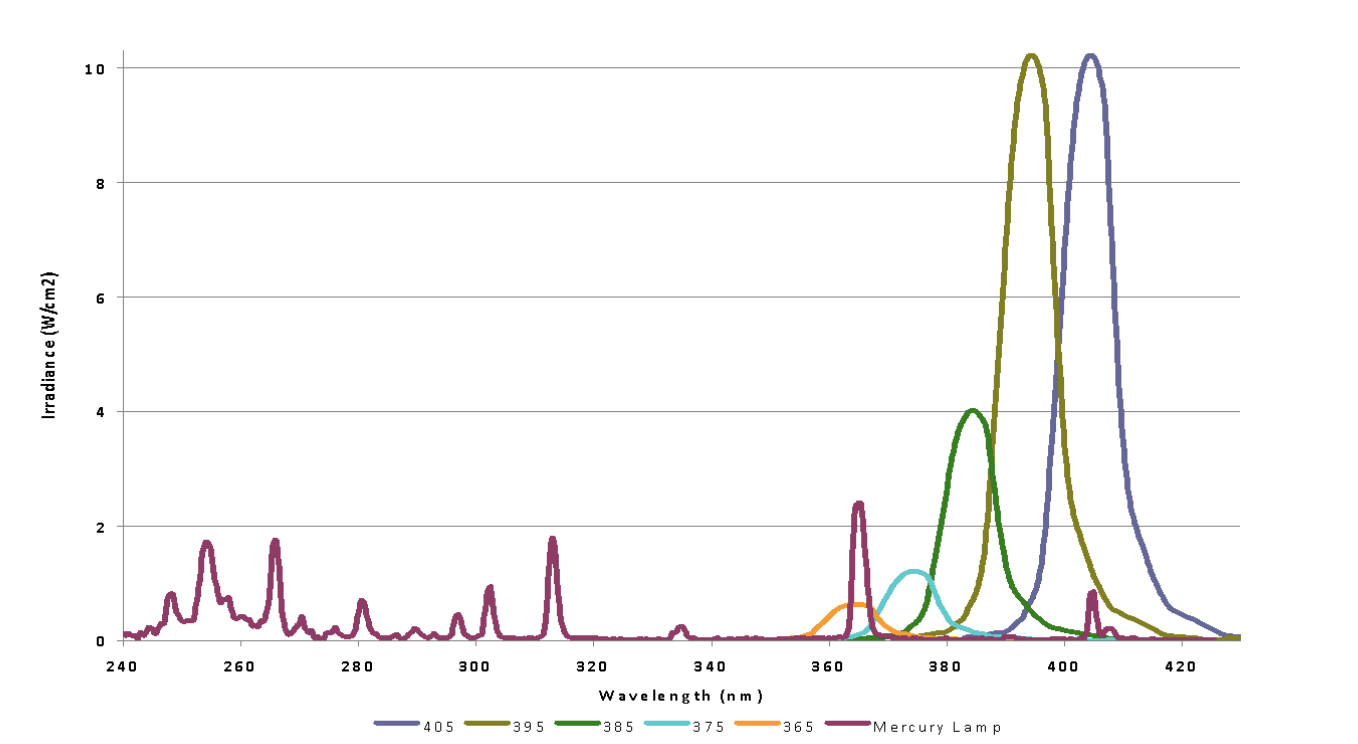

In the diagram below a traditional Mercury vapour lamp (red) offers a broad spectrum of high energy light that covers quite a large amount of the photoinitiators used within the industry. Whereas, UV LED’s (other colours) have a much narrower output band each side of a nominal wavelength.

As can be seen above, LED has a very narrow wavelength range. There is no wasted random wavelengths nor any excessive heat produced by output from unwanted wavelengths such as Infra Red. With LED however a more precise formulation is needed, matched to the correct wavelength.

Credit to MDPI.com for the diagram

In the initial phases of LED coating development, it is true there were some significant challenges. There were limited initiators available and those that did perform tended to yellow quite badly which for clear coatings was a major drawback. It is fair to say the technology has matured and there is now a wider availability of initiators and synergists to aid in the construction of a perfect cocktail.

Now we have our energy wavelength and initiator matched! We can kick our reaction into play and create a polymer right? Oh and what was that word synergist that was thrown into the last paragraph?

Synergists

This is probably the most critical part of the formula, with all UV curing technology there’s something in the air that can spoil the reaction, like a fly in the cocktail.

This is oxygen, oxygen is a very powerful inhibitor to the curing reaction and will stop the reaction rapidly.

There are options available outside of the formulation to resolve this.

If the UV coating is covered with a film blocking the air then there will be no cure inhibition, but care must be taken that the film is transparent to UV wavelengths. This may be difficult or impossible to apply in a Production process.

Air can be purged from the system by using nitrogen to create an inert blanket, but this significantly increases both the capital and running costs of the UV curing system, further it reduces the flexibility and practicality for many widely used applications. For example, in Sheetfed applications it is difficult to create a Nitrogen inerted zone due to the large apertures at the entry and exit of the zone.

The chemical solution is to add nitrogen to the formulation, not literally, as nitrogen is a gas but in the form of a nitrogen containing molecule, amines. (Commonly referred to as a synergist)

Surface Cure/ Through cure

The properties of surface curing are particularly relevant to UV coatings, being the layer that we touch and feel and are exposed to the elements. It is this layer that is expected to give durability to print and friction characteristics.

There are nuances between Mercury and LED energy that play an important part in the reaction mechanism.

LED curing is lower energy and provides longer wavelength energy than provided by higher power lower frequency mercury lamps.

This gives a deep thorough cure into the ink or coating film and provides advantages in terms of adhesion (particularly for difficult substrates). One anecdote from the Inkies is the extremely challenging adhesion problems of opaque white to plastic substrates which were resolved overnight by switching to LED lamp systems.

It is well noted that the longer wavelengths can suffer from poorer surface cure without an optimized formulation. There can be the same percentage of cure overall but to feel the LED

The coating will appear “less cured” this is not actually the case, but the surface is less cross-linked so gives a softer feel than if cured under a mercury lamp.

Should this “less cured” feel be unacceptable then a hybrid curing may be considered, using the shortwave energy of a mercury lamp to enhance the crosslinking of the surface of the coating. UV LED is still under development and shortwave (UVC) dies are a key objective for diode manufacturers as there is commercial demand, not only from the curing market but also from disinfection and life sciences applications.

With the knowledge shared in this document, it can be seen that the parameters can be modified, creating a harder more reactive system, compensating for all the variables and creating the perfect cocktail optimised for any LED System.

It is important to note that LED curing technology is designed to cure with lower energy which makes the products more sensitive to ambient light. It is important to shield the products from factory lighting when opened.