Phoseon: TargetCure™ Technology for Stable, Consistent, Precise Curing

Today’s air-cooled LED light sources have grown in demand and current applications have presented challenges in over and under-curing of materials, along with the degradation of LED output over time. To ensure users have high-performance and consistently accurate products, Phoseon has developed TargetCure Technology. TargetCure Technology uses proprietary and patented Phoseon innovations to provide users the precise and predictable UV output they demand from the market leader. This precise curing ability remains stable across ambient operating temperatures and continually monitors the lamp’s efficiency to adjust the output over the lamp’s lifetime. TargetCure Technology means reliable UV output and less monitoring of defects. This reliable UV output and less monitoring of defects lead to higher yields and profitability.

Why is TargetCure™ Technology Important for Converters?

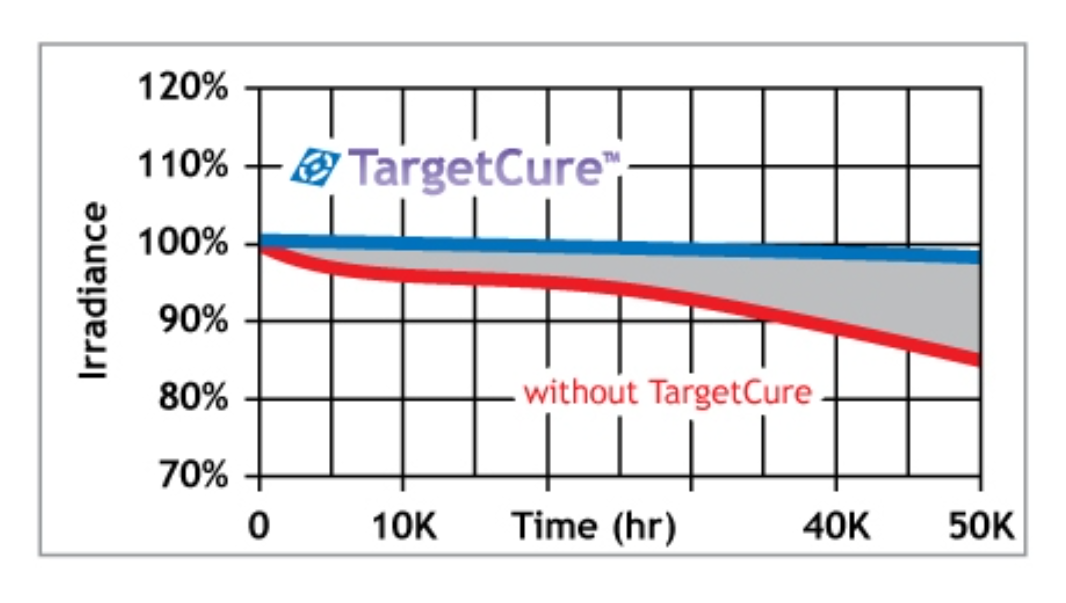

Stable Curing Over the Lifetime of the Unit:

Over time, UV output slowly degrades. TargetCure Technology continually monitors the lamp’s efficiency and adjusts output as it ages, providing stable output for a longer period of time.

Consistent Through Temperature Variation:

As ambient air temperature rises, irradiance lowers, producing under-cured material. TargetCure Technology provides stable output through seasonal and daily temperature variations.

Precise Curing When the Lamp is Turned On:

When air-cooled products are first turned on, they overshoot the target irradiance resulting in over-cured and brittle material. TargetCure Technology delivers precise irradiance, eliminating overshoot, providing a consistent and reliable cure.