FuturePrint Inspiration Sessions: Sustainability is Not Tomorrow’s Problem – BOBST is Ready Today

Sustainability pledges have been made by organizations all over the world. Now, these pledges need to be met.

This isn’t tomorrow’s problem. We cannot simply rely on tomorrow’s technologies and innovations to address all of our sustainability needs. We must look at which current solutions we deploy to tackle sustainability in a more pragmatic manner today. We need to see sustainability as an ongoing mindset and opportunity, and not something to put off until all the answers are clear. At BOBST, we are ready.

Progress in packaging materials

Environmental and sustainability issues are at the top of the agenda of governments, companies, and individuals all over the world. There is no need any longer to debate the importance. We know that the qualities that make plastics so suited for packaging – versatility, durability, impermeability – also make them very environmentally unfriendly; non-biodegradable and challenging to recycle. It is a particular challenge for flexible packaging such as that used for food packaging, where the high barrier protection against oxygen and water that prevents deterioration is currently provided by multi-layer, multi-material packaging, which cannot be recycled. The light weight and food contamination associated with so much flexible packaging also makes it less appealing for collection and recycling.

BOBST has been working hard with partners to replace non-recyclable high barrier multi-material packaging structures with mono-material alternatives designed for recycling.

Partners involved in this effort include Argha, Brückner Maschinenbau, Constantia, Dow, Elba Mitsui Chemicals, ESI, Hosokawa Alpine, Indopoly, Michelman Danaflex and Sun Chemical. We first launched several samples of mono-material standup pouches (MDO PE, BOPE, BOPP and CPP) at K 2019. BOBST and many of the partners involved continued their considerable investment and research to progress further, to ensure all industry requirements are met in terms of processability, barrier, safety and optical quality. In 2021, we together launched the ‘Generation 2.0’ samples of high barrier flexible packaging solutions designed for recyclability, taking us to our ultimate goal of being able to provide completely recyclable solutions to replace non-recyclable packaging. We are ready to engage with customers.

oneBARRIER

As well as developing novel mono-materials, we are also investigating how to optimize existing options for recyclability. Polyethylene (PE), polyethylene terephthalate (PET) and polypropylene (PP) are internationally recyclable. oneBARRIER is a family of new alternative and sustainable solutions that BOBST developed with its partners, the first of which is a high barrier mono-material full PE transparent or metallized solution as an alternative to metallized polyester film. Ethylene-vinyl alcohol copolymer (EVOH) is a polymer with good barrier properties, but EVOH based films can be difficult to recycle because coextruded EVOH layers are typically rather thick. oneBARRIER is producing EVOH-free solutions for high barrier full mono-material PE, with the non-mono material content reduced, hence maximizing the amount of PE. Through this, we provide a packaging structure that is recycling ready and economical while ensuring exceptional barrier performances.

Zero-fault packaging

The essence of being sustainable is reducing waste and optimizing waste management. Because of this, ‘zero-fault’ packaging, which means right first time, every time, is a key goal. There is huge potential to further optimize packaging production in this way.

Solutions like the Digital Inspection Table or the BOBST ACCUCHECK technology should be deployed systematically. The accuracy of these solutions helps to eliminate expensive, reputation-damaging recalls and waste generation. And the Return on Investment of such solutions is almost immediate. Such solutions will be essential when sustainability is viewed in a more holistic manner and preventing waste is a prerequisite.

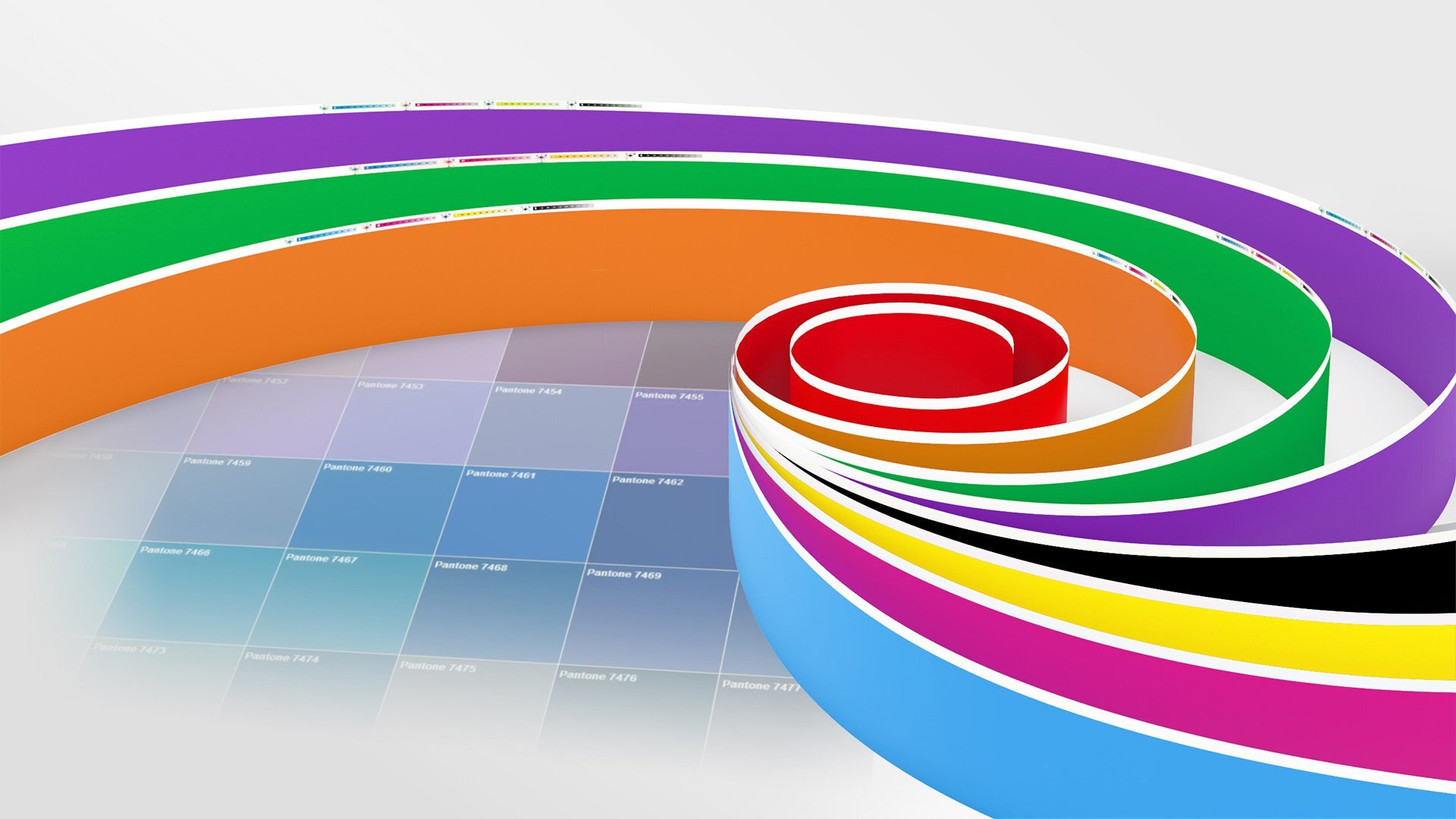

oneECG

Ink usage is another key focus for sustainability efforts. The BOBST’s Extended Color Gamut (ECG) technology deployed across analogue and digital printing processes in label, flexible packaging, folding carton and corrugated board industries enables color consistency in a stable, repeatable and consistent way irrespective of the operator’s skill. But the additional benefit is the major savings on ink usage – up to 30% - and a dramatic reduction of ink waste. With oneECG, brand’s colors will be consistent irrespective of the printing process, the substrate, and the country where production is done and all this at lower cost with less waste. Again, it is likely that such solutions will be deployed systematically in the future.

Water-based inks

Water-based inks are seen as more environmentally friendly – and rightly so. For example, at BOBST we have developed inks which can be used in Gravure flexible packaging. On the BOBST RS 5003, water-based inks greatly reduce VOC (volatile organic compound) emissions as these most often contain a maximum of 30% solvents in the formula. Not only does this reduction protect our planet from pollution, it also makes for a safer and healthier working environment for operators. In CI Flexo, water-based ink printing is also possible and if you wonder about the productivity, speeds of up to 600 linear meter / minute can be achieved on the EXPERT CI

To conclude, sustainability is a mindset, and we cannot wait for tomorrow’s innovations to provide all the solutions. Brand owners and converters need to act now, changing the way packages are designed and produced. At BOBST, we believe that the current solutions are enabling major waste reductions without increasing costs and these innovations are commercially available everywhere in the world. So, let’s start 2022 in a positive manner looking at all what is possible today to reduce our environmental footprint.

By Francois Martin, Bobst Group Marketing & Communication Manager