How UV Enables the World Around Us

Are you aware of how often you benefit from UV light in your day-to-day life?

When ultraviolet light is mentioned, many people immediately think of natural sunlight, but UV radiation is also used in many applications.

Excelitas develops “light” technologies that get integrated into equipment and manufacturing processes to engage, enable, and excel the world around us. Here are some examples of where UV light technology from Excelitas is used to manufacture products you are surrounded by every day.

The Grocery Store

If you walk inside the grocery store, most of the items on the shelves have been printed and UV cured using “light” technology.

Labels & Packaging

Cans

Bottles

Containers

Tubes

Posters & signage

UV curing light technology can be utilized for printing on labels, flexible films, boxes, cartons, corrugated containers, and a wide variety of other packaging materials. Decorative printing applications enhanced by UV technology create product differentiation and increased visual impact. Decorative printing processes allow for high gloss, matte and holographic effects.

Automotive Manufacturing

UV light technology is used throughout the car manufacturing process for both the interior and exterior.

Switches, handles, trim

Steering wheel

Doors

Mirrors

Windshield

Seats

Airbags

Paint

Brake pads

Infrared and UV technology offer many opportunities to optimize part production for vehicle interiors. The interior of a car should be comfortable and user-friendly. An astonishing number of manufacturing steps for dashboards, handles, switches, seats, carpets and consoles benefit from infrared heat and UV curing technology. Infrared heat improves many process steps such as deburring, forming, laminating, and drying or activating adhesives and coatings.

UV light curing of inks and coatings on interior components such as switches, handles and trim pieces improves durability and aesthetics. Many steps in the production and finishing of automotive interior parts are time-consuming and energy intensive. And in the end, the car owner demands good quality at a reasonable price.

Your Home

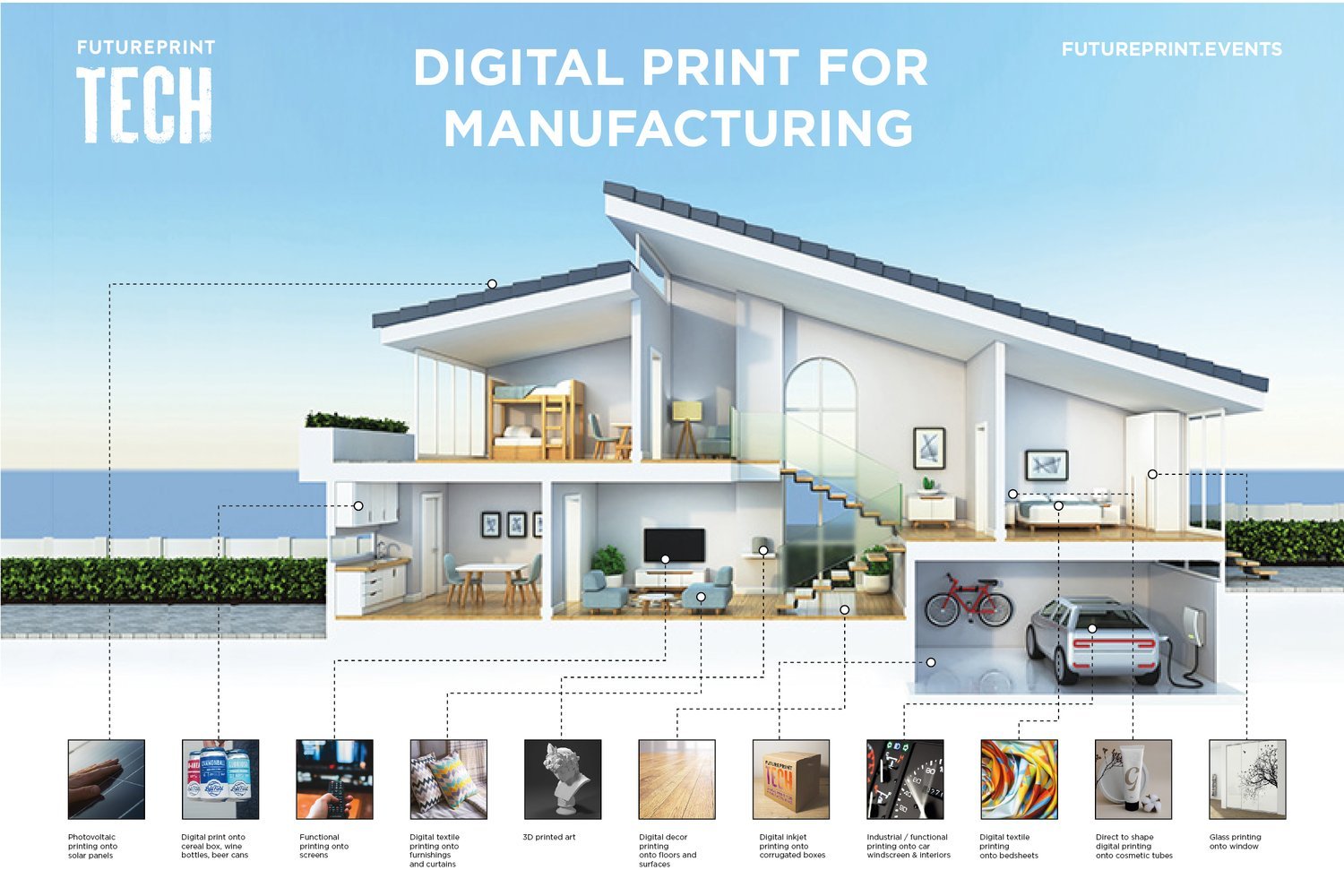

UV light curing technology is utilized in digital printing for manufacturing everyday items throughout a home. Digital print for manufacturing is the type of digital printing used in manufacturing, whether for functional or decorative purposes. The house diagram below from FUTUREPRINT illustrates the wide range of applications that utilize digital printing in the manufacturing process.

Solar panels

3D printed art

Cosmetic tubes

Glass windows

Cereal box, wine bottle, beer can

Flooring

Corrugated boxes

Car interior and exterior

Light technology is utilized in manufacturing processes for UV curing, Infrared drying, and many other applications. Excelitas develops a wide range of integrated light technologies that offer significant gains in productivity and efficacy, yet they are often unseen because they are integrated into a machine.

For more information about life-enriching photonic technologies, visit the Excelitas website.