Dedicated décor technology gives designers near-complete freedom

Paul Willems took part in 'Printed Interior Décor: An Untapped Opportunity?', a FuturePrint panel discussion on October 13th 2020.

We asked Paul to explain more…

Interior decoration makes up the atmosphere, both the look and feel of a space. It's a growing market and one we're excited to explore at Roland. Digital printing technology has driven development and innovation, with fantastic results. Naturally, we initially looked at the interior décor sector through a sign and graphics lens, but there are some limitations on standard sign products; they are simply not designed for the décor sector.

To that end, we got to work to develop a new printing solution, one that meets five key and specific requirements of interior décor. Firstly, broad media compatibility is necessary. Secondly, health and safety compliance is crucial, and very different to that of signage. Next, there should be ease of use and high levels of safety, from the start of the process to the print's installation in a room. Fourthly, application durability is essential. Finally, productivity should be high and cost of operation low.

Next we identified four main segments: home decoration – consumers buying directly for their houses and apartments; commercial spaces such as retail, museums, restaurants and hotels; government and public buildings including schools and hospitals; and the industry and corporate sector, such as offices and showrooms.

The applications in these different segments are very similar, but there are some big technical differences. For instance, homeowners typically want to customise their environment permanently, so printed graphics need to offer longevity and durability. But commercial customers want to change their messaging and atmosphere frequently, possibly every season, so graphics must be easily removable and economical to produce.

There also important distinctions between health and safety regulations and concerns: a shopping mall will be different to a bedroom to a kindergarten to a hospital. How a business deals with the customer, buying motivations and regulatory context are all dependent on the segment, rather than the application.

Our R&D has resulted in the EJ-640 DECO decoration printer. We started with a clean slate to develop a new set of ink types, our INKU DECO water-based resin inks.

They are very low-VOC and odour-free to meet air purity health and safety requirements, and are fast-drying so materials can be handled immediately without scuffing. We have worked with key media manufacturers to ensure the EJ-640 DECO's prints pass standard tests on light fastness and wash resistance, to perform as they need to.

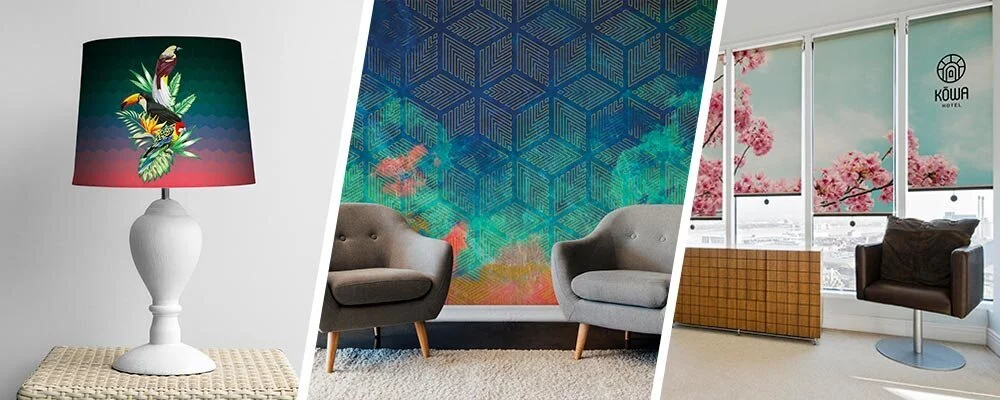

By engineering a new printing system specifically for interior décor, we can help the market evolve. Designers are the innovation engine, but previously had to work with available materials; with digital technology we can turn that paradigm upside down. Designers today have near-complete freedom over unique image content, patterns and shapes, how their design fits a space.

There is an opportunity to use a variety of materials for different elements of their design – think wallcoverings, sun blinds and other elements that either fit together or create a perfect contrast. Concept proofs and complete designs can be turned around very quickly.

The creation and execution process now go hand in hand, providing customer satisfaction and greater power to the designer.

It's an opportunity for designers but also for our industry, particularly for PSPs, to execute and realise these wonderful designs. It is an opportunity to look forward to.